Rear axles transmit engine power from the drive line to the rear wheels, multiply torque

& serve as a major load carrying member. The efficient performance if these functions

are of major importance in the design of truck rear axles.

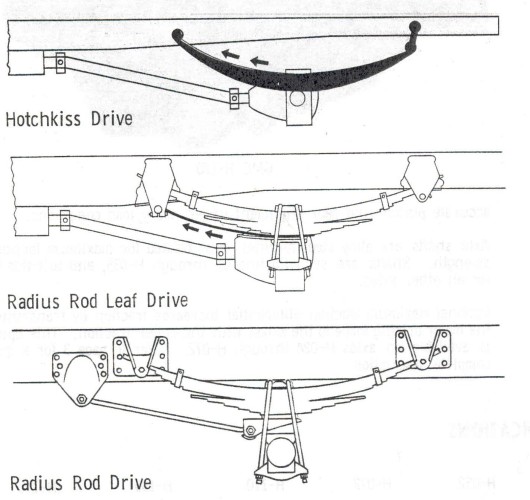

Drive types are Hotchkiss & Radius Road. Hotchkiss drive is generally used in light duty

service where extreme conditions are not encountered. In this type of drive axle all

oscillation thrust, braking thrust, & road shock are absorbed by the rear springs.

Radius rod drive is used in some light, but most frequently in medium & heavy duty service.

Its functions serve to maintain axle alignment, the transfer of axle driving & braking thrust

& some road shock to the frame. In this case springs support & cushion load only. The link

between axle & frame is control arms for coil spring rear suspension, radius rod leaf for

vari-rate springs, radius rods for link type suspension, & torque rods for tandem suspensions.

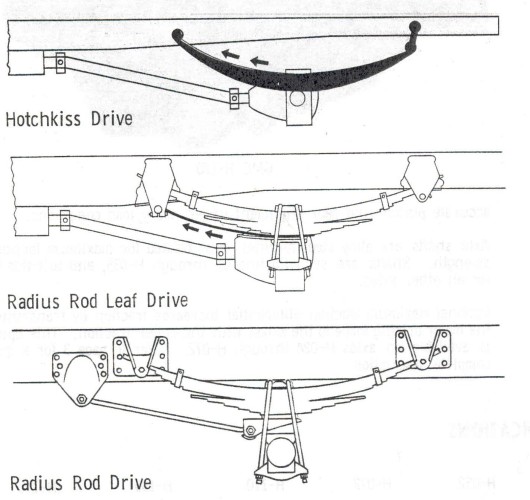

A rear axle is designated ad Hypoid or Spiral Bevel according to the type of gearing used.

Hypoid axles have drive pinion offset in respect to the centerline of the ring gear.

Spiral Bevel axles have the drive pinion on center with the ring gear.

Types of rear axles used are single reduction, double reduction, & two-speed. Single reduction axles

are those that obtain reduction through a single set of gears. They are most frequently used because

of low initial cost, light weight, have fewer parts to maintain, & are an efficient transfer of

power. Single reduction axles are used light & heavy operations but are not recommended in cases

where extremely low ratios are necessary.

Operations requiring increased low gear pulling ability, either single or tandem drive axles, frequently

require greater ratios than is practical for single reduction axles. A double reduction axle with a

second set of helical gears added, achieves this end through two stages of reduction.

Operations requiring versatility beyond the performance ability of single reduction axles may use a

two-speed axle with a normal operating ratio for high speed work & a low ratio for increased pulling

power. The high speed ratio is through a conventional pinion & ring gear. Increased reduction for

low speed is gained through a set of planetary gears that can be engaged, or shifted, by the driver.

Another type is the double reduction two-speed axle with double reduction gearing in both high &

low range. This type has a pinion & ring gear combined with two helical gear sets with different

ratios, producing when shifted, two different final reductions.

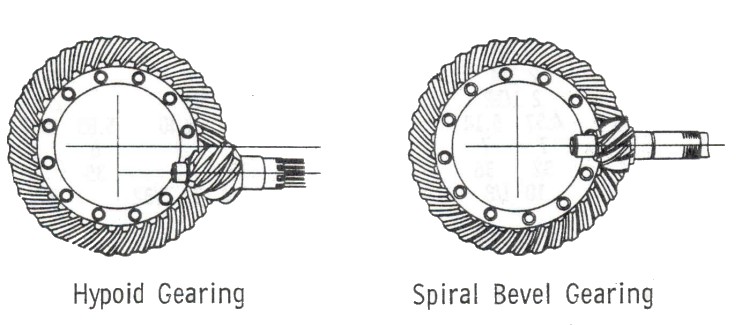

Axles fall into two basic design classes, semi-floating & full-floating, as determined by wheel

bearing support at outer ends of the axle. Inner support of axle shafts is the same for both types,

that is, closely fitted into mating splines of the differential side gears which in turn are supported

by the differential carrier. Semi-floating axles have wheel bearing located between axle shafts &

housing. Thus the shaft supports part of the load as well as turning the wheels. Semi-floating

axles are used for light duty work.

Full-floating axles are used in medium & heavy duty trucks. Axle housing in this type carries all

the weight while axle shafts serve to turn the wheels. Wheel hubs rotate on bearing on the outside

of the axle tube, allowing shafts to literally float within the housing.

When you start thinking about gear ratios you need to look at the whole picture, not just transmission

gearing, but rear axle gearing & tire size play a lot into the equation too. There is a formula or

two for this, This is the one found in the 1965 GMC Dealer data book;

RPM x 60 divided by Final Ratio x tire revolutions pre mile = Miles pre hour.

3500 x 60 (210000) / 3.54 x 745 (2637.3) = 79.63

To get "tire revolutions pre mile" paint a spot on the tire & ground, then roll the truck forward

tell the paint spot on the tire meets the ground again, then paint the ground there. Move truck out

of the way & measure the distance between paint spots in inches, then divide that number into how

many inches in a mile (63360"). That will give you "tire revolutions pre mile".

So lets look at a GMC 1/2 ton truck with rear axle ratio of 3.54:1. We also know this info; 4 speed SM420

transmission, 1st = 7.06:1, 2nd = 3.58:1, 3rd = 1.71:1, 4th = 1.00:1. With this set up, that will give

you a final drive gear ratios of; 1st = 24.99:1, 2nd = 12.67:1, 3rd = 6.05:1, 4th = 3.54:1. Engine max

RPM of 3500, 15 inch tire will have a revolutions pre mile of around 745. So our first number will be

3500 x 60 = 210000, the 2nd number in 4th gear 3.54 x 745 = 2637.3, so now take 210000 / 2637.3 = 79.63 mph.

Top speed in low gear would be 210000 / 18617.55 = 11.28 mph. Just for the record, 16" tires = 705 rpm.

The following Tables cover Drive Axles used by GMC trucks in the 1000-4000 series trucks,

there are two tables below, one for 1962 & one for 1966. 4000 models cover All prefix

letters, D-, I-, KV, H, HI & D-4100 models. KV-4000 is front drive axle data.

|

Truck Model |

Manufacturer |

Model |

Standard Ratio |

Optional Ratios |

Style |

Reduction |

Lock Option |

Weight Rate |

Oil Capacity |

|

1000 |

Spicer |

44 |

3.07:1 |

3.54:1 |

Hypoid |

Single |

Powr-Loc |

3500 lbs |

3-1/2 pints |

|

K-1000 Rear |

Spicer |

44 |

3.92:1 |

No |

Hypoid |

Single |

Powr-Loc |

3500 lbs |

3-1/2 pints |

|

K-1000 Front |

GMC |

FH-033 |

3.92:1 |

No |

Hypoid |

Single |

No |

3300 lbs |

4-1/2 pints |

|

1500 |

Spicer |

60 |

4.56:1 |

4.10:1 |

Hypoid |

Single |

Powr-Loc |

5500 lbs |

5-1/2 pints |

|

K-1500 Rear |

Spicer |

60 |

4.56:1 |

No |

Hypoid |

Single |

Powr-Loc |

5500 lbs |

5-1/2 pints |

|

K-1500 Front |

GMC |

FH-035 |

4.56:1 |

No |

Hypoid |

Single |

No |

3500 lbs |

4-1/2 pints |

|

2500 |

GMC |

H-072 |

4.57:1 |

5.14:1 |

Hypoid |

Single |

No |

7200 lbs |

6-1/2 pints |

|

3000 |

GMC |

H-110 |

5.43:1 |

No |

Hypoid |

Single |

No |

11,000 lbs |

14 pints |

|

3500 |

GMC |

H-130 |

5.43:1 |

6.60:1 |

Hypoid |

Single |

No |

13,000 lbs |

16-1/2 pints |

|

3500 2-speed |

Eaton |

13800 |

5.83:1-8.11:1 |

No |

Hypoid |

Single Hi |

No |

13,000 lbs |

13 pints |

|

4000 |

GMC |

H-150 |

6.17:1 |

7.20:1 |

Hypoid |

Single |

No |

15,000 lbs |

20 pints |

|

4000 |

Timken |

G-161 |

6.17:1 |

7.20:1 |

Hypoid |

Single |

No |

16,000 lbs |

21 pints |

|

4000 2-speed |

GMC |

T-150 |

6.40:1-8.72:1 |

5.83:1-7.95:1 |

Hypoid |

Single Hi |

No |

15,000 lbs |

18 pints |

|

4000 2-speed |

Timken |

G-361 |

6.16:1-8.48:1 |

No |

Hypoid |

Double |

No |

16,000 lbs |

26 pints |

|

Truck Model |

Manufacturer |

Model |

Standard Ratio |

Optional Ratios |

Style |

Reduction |

Lock Option |

Weight Rate |

Oil Capacity |

|

1000 |

Spicer |

44 |

3.07:1 |

3.54:1 |

Hypoid |

Single |

Yes |

3500 lbs |

3-1/2 pints |

|

I-1000 |

Spicer |

44 |

3.54:1 |

3.07:1 |

Hypoid |

Single |

Yes |

3500 lbs |

3-1/2 pints |

|

G-1000 |

GMC |

H-024 |

3.36:1 |

4.11:1 |

Hypoid |

Single |

Yes |

2400 lbs |

3-1/2 pints |

|

Optional G-1000 |

GMC |

H-029 |

3.73:1 |

4.11:1 |

Hypoid |

Single |

Yes |

2400 lbs |

4-1/2 pints |

|

Optional 1000 I-1000 |

Spicer |

60-35 |

3.54:1 |

No |

Hypoid |

Single |

Yes |

3500 lbs |

3-1/2 pints |

|

K-1000 Rear |

Spicer |

44 |

3.54:1 |

No |

Hypoid |

Single |

Yes |

3500 lbs |

3-1/2 pints |

|

K-1000 Front |

GMC |

FH-033 |

3.54:1 |

No |

Hypoid |

Single |

No |

3300 lbs |

4-1/2 pints |

|

1500 |

Spicer |

60 |

4.10:1 |

4.56:1 |

Hypoid |

Single |

Yes |

5500 lbs |

5-1/2 pints |

|

I-1500 |

Spicer |

60 |

4.56:1 |

No |

Hypoid |

Single |

Yes |

5500 lbs |

5-1/2 pints |

|

K-1500 Rear |

Spicer |

60 |

4.56:1 |

No |

Hypoid |

Single |

Yes |

5500 lbs |

5-1/2 pints |

|

K-1500 Front |

GMC |

FH-035 |

4.55:1 |

No |

Hypoid |

Single |

No |

3500 lbs |

4-1/2 pints |

|

2500 |

GMC |

H-072 |

4.57:1 |

5.14:1 |

Hypoid |

Single |

Yes |

7200 lbs |

6-1/2 pints |

|

I-2500 |

GMC |

H-072 |

5.14:1 |

No |

Hypoid |

Single |

Yes |

7200 lbs |

6-1/2 pints |

|

3500 |

GMC |

H-110 |

6.17:1 |

6.60:1 |

Hypoid |

Single |

No |

11,000 lbs |

14 pints |

|

3500 |

GMC |

H-135 |

6.40:1 |

No |

Hypoid |

Single |

No |

13,500 lbs |

16-1/2 pints |

|

3500 |

GMC |

H-150 |

6.17:1 |

7.20:1 |

Hypoid |

Single |

No |

15,000 lbs |

20 pints |

|

3500 2-speed |

GMC |

T-150 |

5.83:1-7.95:1 |

6.50:1-8.85:1 |

Hypoid |

Single Hi |

No |

15,000 lbs |

18 pints |

|

4000 |

GMC |

H-150 |

6.17:1 |

7.20:1 |

Hypoid |

Single |

No |

15,000 lbs |

20 pints |

|

4000 |

Rockwell |

G-161 |

6.17:1 |

7.20:1 |

Hypoid |

Single |

No |

16,000 lbs |

21 pints |

|

4000 |

Eaton |

16121 |

6.14:1 |

7.17:1 |

Spiral |

Single |

No |

17,000 lbs |

26 pints |

|

4000 2-speed |

GMC |

T-150 |

5.83:1-7.95:1 |

6.50:1-8.85:1 |

Hypoid |

Single Hi |

No |

15,000 lbs |

18 pints |

|

4000 2-speed |

Rockwell |

G-361 |

6.16:1-8.48:1 |

6.61:1-9.09:1 |

Hypoid |

Double |

No |

16,000 lbs |

21 pints |

|

4000 2-speed |

Eaton |

16121 |

5.75:1-7.75:1 |

6.14:1-8.54:1 |

Spiral |

Single Hi |

No |

17,000 lbs |

26 pints |

|

KV-4000 Front |

Coleman (Rockwell) |

FD-070 |

6.20:1 |

No |

Hypoid |

Single |

No |

7,000 lbs |

21 pints |

Coleman Front Drive axle uses Rockwell E-100 Differential & Carrier assembly.

~ 6066 GMC Trucks ~ 6066 GMC Trucks ~ 6066 GMC Trucks ~ 6066 GMC Trucks ~ 6066 GMC Trucks ~ 6066 GMC Trucks ~ 6066 GMC Trucks ~ 6066 GMC Trucks ~

Information About GMC Truck Drive Trains

|

GMC Big Block V6 |

1960-1966 |

|

~ 6066 GMC Trucks ~ 6066 GMC Trucks ~ 6066 GMC Trucks ~ 6066 GMC Trucks ~ 6066 GMC Trucks ~ 6066 GMC Trucks ~ 6066 GMC Trucks ~ 6066 GMC Trucks ~

© 2000-2008 6066 GMC Trucks. Last Updated July 21, 2008.